Queenly likes to share her knowledge of society with others. She is always reading up on the latest news and trends, so she can provide insights and perspectives that help people understand the world around them. Coreen is a great listener, and she loves to help people grow and develop.

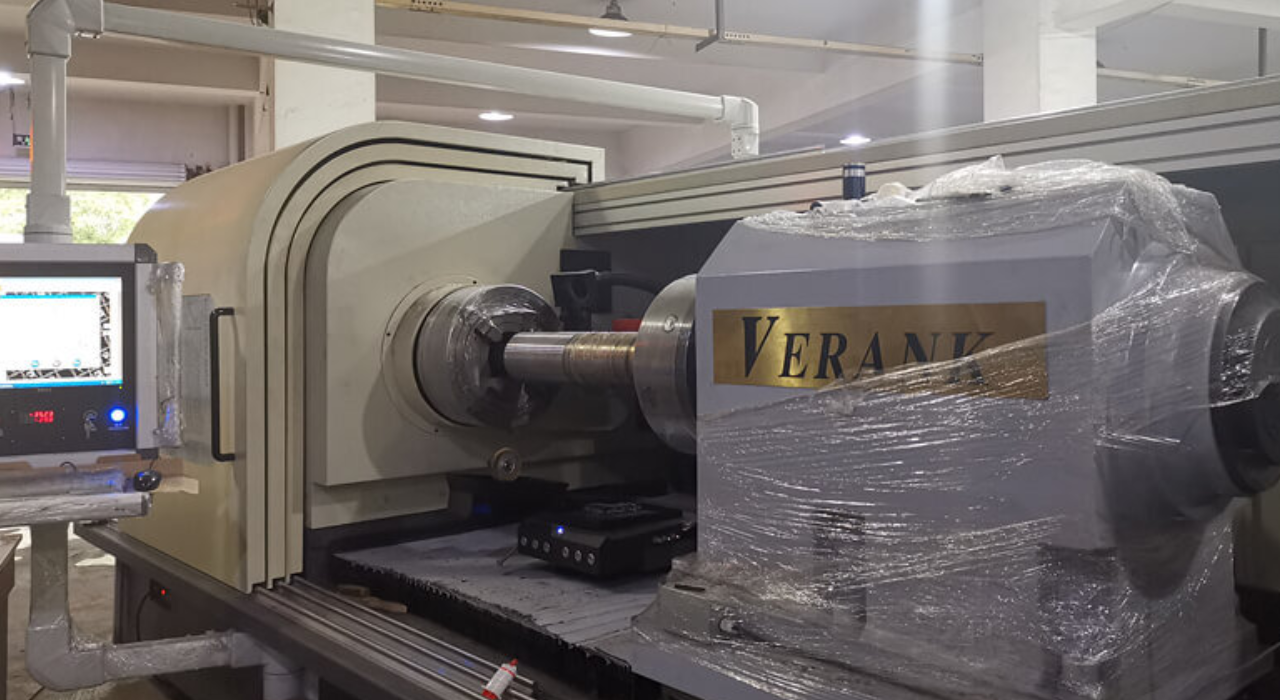

Laser engraving producers are pivotal in the development and deployment of the current generation, which revolutionizes how substances are marked and custom-designed. The manufacturers focus on designing, generating, and distributing laser engraving structures that cater to a large selection of industries and programs internationally.

Manufacturers offer a diverse variety of machines, from compact computer fashions appropriate for small businesses and hobbyists to robust, industrial-grade structures capable of high-volume production. laser gravure is a flexible and precise approach to etching designs, text, or images onto a spread of materials. The technology makes use of a targeted laser beam to remove material from the surface, leaving a permanent mark. The forms of materials that can be laser engraved are numerous, each with its own traits and applications.

Materials That Can Be Engraved With Lasers

This article explores the various materials that may be laser engraved, their particular properties, and the nuances of engraving each kind.

Metals

Laser engraving on metals is ideal for producing high-contrast and durable markings. Anodized aluminum gives colorful shades and clean engravings, making it ideal for nameplates and electronics. Stainless steel is extensively used for business tags, scientific devices, and kitchenware because of its polished, professional finish. Brass and copper, recognized for their aesthetic enchantment, are famous for plaques and decorative items. Fiber lasers are generally employed for their precision and efficiency in metallic engraving.

Copper

Laser engraving on copper yields precise, detailed outcomes with a wonderful look. Regarded for its rich color and sturdiness, copper is usually used for plaques, nameplates, and ornamental items. The engraving method can create an excessive assessment end that highlights intricate designs. Through the years, engraved copper can increase its patina, adding to its aesthetic enchantment. Fiber lasers are often used to engrave copper, ensuring precision and clarity inside the completed product.

Stainless-steel

Laser engraving on stainless steel provides sharp, clean, and durable results, making it ideal for commercial tags, medical gadgets, and kitchenware. The material’s resilience ensures durability, while the engraving method provides a high-comparison, polished finish. Fiber lasers are typically used for their precision and capability to handle the hardness of chrome steel. This technique is ideal for growing exact, everlasting markings that withstand wear and tear and environmental elements.

Ceramics

Laser engraving on ceramics produces crisp, permanent markings, perfect for tiles, mugs, and ornamental gadgets. The process involves disposing of a skinny layer from the surface, revealing a contrasting color underneath. This method ensures specified, high-contrast designs that are both long-lasting and resistant to fading. CO2 lasers are generally used for ceramic engraving, providing precision and performance for complex patterns and text.

Acrylic

Laser engraving on acrylic creates particular, frosted designs that stand out against the cloth’s clean floor. To be had in clean and colored types, acrylic is right for signage, awards, and ornamental panels. The laser method can produce intricate information and sharp edges, enhancing the visual appeal. CO2 lasers are usually used for their effectiveness in engraving and reducing acrylic, ensuring first-rate, polished outcomes for various packages.

Leather

Laser engraving on leather-based products produces complicated, designated designs with various shades and depths. Natural leather engraves rather nicely, giving it a rich, textured look. This technique is famous for personalizing gadgets, which include wallets, belts, journals, and patches. Both natural and synthetic leathers can be engraved, although the consequences may additionally vary. CO2 lasers are typically used for their precision and capability to deal with the particular texture and composition of leather-based.

Rubber

Laser engraving on rubber is ideal for growing custom stamps, seals, and gaskets. The manner produces easy, specific cuts and engravings, ensuring high element and durability. CO2 lasers are usually used due to their efficiency and potential to handle the material’s flexibility. Engraved rubber can stand up to repeated use and various conditions, making it appropriate for commercial applications, promotional gadgets, and customized rubber products.

Sum Up

A variety of materials can be etched with designs using the strong and flexible laser engraving technique. Each material has its own specific properties and program. The selection of fabric depends on the intended use and desired aesthetic, however, the precision and permanence of laser engraving make it an extremely good choice for many projects. Whether or not for commercial, business, or personal functions, laser engraving affords a terrific, long-lasting, and customizable solution.